IIGS Qualitätsmodell

In the past, the IIGS investigated how to describe the quality of spatial information or data within different research projects (see also the description of the IIGS data quality model [reference]). In recent years, the focus of this work was a bit extended because modern quality management systems also require a well-defined description of the quality of the products or processes in question. In this context, a good overview about existing quality management (QM) systems in general and such QM systems well appropriate for spatial data in particular has been gathered at the institute. A short introduction and overview is given in the next sections.

Introduction to Quality Management - ISO 9000 family

According to ISO 9000, quality management is defined as “coordinated activities to direct and control an organization with regard to quality.” Thereby quality is the “degree to which a set of inherent characteristics fulfills requirements.” “Direction and control with regard to quality generally includes establishment of the quality policy and quality objectives, quality planning, quality control, quality assurance and quality improvement.”

Some basic requirements to the implementation of quality management are specified in the ISO 9000 standards family which helps “to implement and operate effective quality management systems.” ISO 9000 describes fundamentals of quality management, ISO 9001 specifies requirements for a quality management system for organizations and ISO 9004 provides guidelines which completes the requirements of ISO 9001.

The ISO 9000 family only defines requirements to a quality management system but not to the products, it is only a general guideline for implementation of such a system. Concrete product requirements are defined by customers, authorities or the organization itself.

Existing quality management concepts

For the realization of the quality management described in the ISO 9000 series quite a big number of different QM concepts can be used. In the following, three existing concepts which are basically suitable for a QM for spatial data are introduced exemplarily. After that, a new concept that is based on the latter QM concepts but was designed to meet the special project requirements of the ROSATTE project will be presented.

PDCA

PDCA (also known as Deming cycle) was developed by William Edward Deming. It consists of the 4 phases plan, do, act and check. Most of the common quality management concepts are based on or derived from the PDCA cycle. The individual phases have been defined in detail in ISO 9001 as

- Plan: establish the objectives and processes necessary to deliver results in accordance with customer requirements and the organization’s policies

- Do: implement the processes

- Check: monitor and measure processes and products against policies, objectives and requirements for the product and report the results

- Act: take actions to continually improve process performance

The phases form a continuous circle for process improvement. Quality assured process development is not addressed in the PDCA concept.

TQM

Total Quality Management, also called TQM, is a management philosophy which is focused on the value-added process. This method is orientated at all persons having requirements to the quality of products: Customers and participants being also internal customers.

Within TQM, the required quality of products is reached by fulfilling all user requirements and wishes. But these requirements change permanently, so there is a continuous need for improvements.

The improvement of quality is reached by formulation of concrete objectives taking into account available quality requirements.

A specification of objectives must always include the following items:

- Concrete formulation of the content

- Time frame

- Responsibilities of the objectives

- Specification of intensity of labor

- Required resources

- Description of general conditions

- How will be measured if the objectives are achieved?

- Kind of documentation

- What will happen after having finished the improvement?

Six Sigma

The origin of the Six Sigma concept lies in the quality engineering for the implementation of a zero defects strategy and leads to a high quality capability of processes.

Six Sigma projects demand a raising user satisfaction by fulfilling the user requirements like Data discovery or conformance with the European INSPIRE directive, that regulates the deployment of Intelligent Transportation Systems (ITS) for road transport. All problems which prevent this objective must be identified so the problems can be eliminated. The general aim is to implement a zero defects strategy. Defects must be avoided to realize all requirements.

There are different methods for realizing a Six Sigma project. Table 1 presents 4 of the most well-known and gives some information about them.

Table 1 - Six Sigma methods

| Method | Description |

| Stand-Alone-Tool (or SAT) | Individual selected tools are used to achieve punctual improvements. |

| DMAIC | Define – Measure – Analyse – Improve – Control/Check: standard method for the improvement of existing processes. Often Six Sigma is only reduced to this method. |

| QuickHit | Short form of DMAIC method which is used to achieve quick and unique effects. These helps to establish acceptance for innovates. |

| Design for Six Sigma (DfSS) | Method for developing new products and processes. |

Project specific Quality Management Systems

In order to account for special project-specific requirements, the IIGS derives customized QM concepts. For example, within the ROSATTE project a QM concept was needed to accompany the project development phase and helps to accomplish the project’s quality requirements. On the other side, the experiences and quality parameter definitions should also be used in the production phase of ROSATTE.

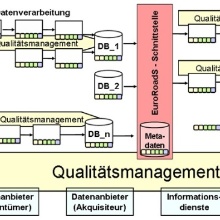

From the above mentioned quality management systems, the Six Sigma method turned out to be most suitable for the special requirements of ROSATTE. It was then further adapted so that finally a two-phase quality management concept was born. Figure 1 gives an overview.

The first phase is based on the Design for SixSigma Methodology (that is also known as DMADV) and can be applied during the development phase of a project / product. The second phase is based on the developed quality descriptions and evaluation methods. It is applied during the production phase that directly follows the development phase. The quality management in this phase mostly cares about quality monitoring and assurance. From the experiences gained within the development phase, also a so-called action plan is derived. The second QM phase is based on the SixSigma DMAIC methodology that probably is the best-known one.

Contact:

Volker Schwieger

Prof. Dr.-Ing. habil. Dr. h.c.Director of the Institute